Effect of Pretreatment on the Profiling of Cassava Peels by Morphological and Chemical Characterization

DOI:

https://doi.org/10.56532/mjsat.v5i4.500Keywords:

Autoclaving, Cassava peel, Cellulose, Reducing sugar, PretreatmentAbstract

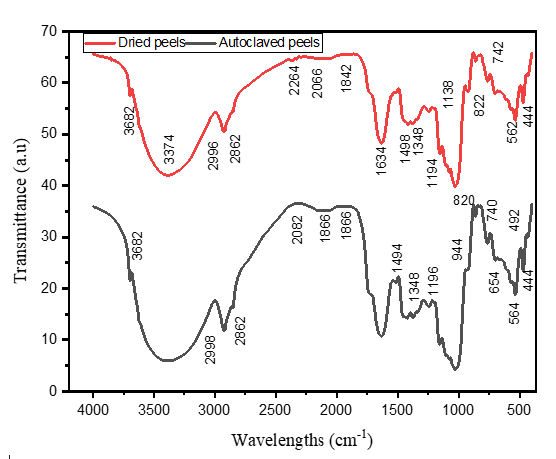

Cassava is mainly grown for its root, whereas the peels are mostly considered a byproduct. Cassava peels, a byproduct of cassava processing, have gained significant attention in recent years as a potential feedstock and other bioproduct. This study investigated the impact of pretreatment on the lignocellulose content, functional groups, morphological characteristics (SEM), chemical composition (XRF), and crystalline phases (XRD) of dried and autoclaved cassava peels. The Chemical analysis showed cellulose content increased from 42.80% to 45.51%, hemicellulose decreased from 25.33% to 19.66%, and lignin content decreased from 15.33% to 10.33% after autoclaving. The autoclaved cassava peels µXRF results also revealed the presence of high iron (Fe) and potassium, as well as traces of manganese at 0.52%, and an amorphous and semi-crystalline structure. Although the SEM images showed no morphological difference between the dried and autoclaved cassava peels. The Brunauer Emmette Teller (BET) analysis indicated a higher surface area of 2.713 m²/g for autoclaved cassava compared to 2.097 m²/g for dried cassava peels. Thermal pretreatment via the autoclave method improved the structural properties and increased the degradable cellulose content of cassava peels. Thus, the cassava peels can be biotechnologically converted into value-added products to maximize effective utilization.

References

T. Mehmood, F. Nadeem, S. A. Qamar, M. Bilal, and H. M. N. Iqbal, “Bioconversion of agro-industrial waste into value-added compounds,” Sustainable bioconversion of waste to value added products, pp. 349–368, 2021. doi: https://doi.org/10.1007/978-3-030-61837-7_22

N. Ismail, N. F. Fauzi, A. Salehabadi, S. Latif, S. Awiszus and J. Müller “A study on biogas production from cassava peel and stem in anaerobic digestion reactor,” International Journal of Environmental Science and Technology, vol. 19, no. 3, pp. 1695–1704, Mar. 2022, doi: https://doi.org/10.1007/s13762-021-03222-4

R. Kayiwa, H. Kasedde, M. Lubwama, and J. B. Kirabira, “Characterization and pre-leaching effect on the peels of predominant cassava varieties in Uganda for production of activated carbon,” Current Research in Green and Sustainable Chemistry, vol. 4, p. 100083, 2021. doi: https://doi.org/10.1016/j.crgsc.2021.100083

N.N. Zulkifli and L. Karim, “Biorefinery Approach for Cassava Peels: A Review,” Malaysian Journal of Science Health & Technology, vol. 8, no. 2, pp. 1–8, May 2022, doi: https://doi.org/10.33102/2022230

Z. Daud, H. Awang, A. S. M. Kassim, M. Z. M. Hatta, and A. M. Aripin, “Comparison of pineapple leaf and cassava peel by chemical properties and morphology characterization,” Adv Mat Res, vol. 974, pp. 384–388, 2014. doi: https://doi.org/10.4028/www.scientific.net/AMR.974.384

N. A. Acheampong, W.G. Akanwariwiak, M. Mensah, B. Fei-Baffoe, F. Offei, J. A. Bentil, A.Z. Imoro, and L.S. Borquaye. “Conversion of cassava peels into bioethanol using the OSTEP approach,” Biomass Convers Biorefin, 2022, doi: https://doi.org/10.1007/s13399-021-02149-7

M. Otache, S. Ubwa, and A. Godwin, “Proximate Analysis and Mineral Composition of Peels of Three Sweet Cassava Cultivars,” Asian Journal of Physical and Chemical Sciences, vol. 3, no. 4, pp. 1–10, Jan. 2017, doi: https://doi.org/10.9734/AJOPACS/2017/36502

V. T. Weligama Thuppahige, L. Moghaddam, Z. G. Welsh, T. Wang, H. W. Xiao, and A. Karim, “Extraction and characterisation of starch from cassava (Manihot esculenta) agro-industrial wastes,” LWT, vol. 182, Jun. 2023, doi: https://doi.org/10.1016/j.lwt.2023.114787.

M. Zhang, L. Xie, Z. Yin, S. K. Khanal, and Q. Zhou, “Biorefinery approach for cassava-based industrial wastes: Current status and opportunities,” Bioresour Technol, vol. 215, pp. 50–62, 2016 doi: https://doi.org/10.1016/j.biortech.2016.04.026

S. Mohd-Asharuddin, N. Othman, N. S. M. Zin, and H. A. Tajarudin, “A chemical and morphological study of cassava peel: A potential waste as coagulant aid,” in MATEC web of conferences, EDP Sciences, 2017, p. 06012. doi: https://doi.org/10.1051/matecconf/201710306012

A. M. Alrefai, R. Alrefai, K. Y. Benyounis, and J. Stokes, “Impact of Starch from Cassava Peel on Biogas produced through the anaerobic digestion process,” Energies (Basel), vol. 13, no. 11, p. 2713, 2020. doi: https://doi.org/10.3390/en13112713

M. Masruri, A. Z. Azhar, I. Rosyada, and A. Febrianto, “The effect of kaffir lime (Citrus hystrix DC) essential oil on bioplastic derived from cassava peel waste,” in Journal of Physics: Conference Series, IOP Publishing, 2019, p. 012015. doi: https://doi.org/10.1088/1742-6596/1374/1/012015

G. S. Aruwajoye, F. D. Faloye, and E. G. Kana, “Soaking assisted thermal pretreatment of cassava peels wastes for fermentable sugar production: process modelling and optimization,” Energy Convers Manag, vol. 150, pp. 558–566, 2017. doi: https://doi.org/10.1016/j.enconman.2017.08.046

A. R. Mankar, A. Pandey, A. Modak, and K. K. Pant, “Pretreatment of lignocellulosic biomass: A review on recent advances,” Aug. 01, 2021, Elsevier Ltd. doi: https://doi.org/10.1016/j.biortech.2021.125235.

L. Lin, R. Yan, Y. Liu, and W. Jiang, “In-depth investigation of enzymatic hydrolysis of biomass wastes based on three major components: cellulose, hemicellulose and lignin,” Bioresour Technol, vol. 101, no. 21, pp. 8217–8223, 2010. doi: https://doi.org/10.1016/j.biortech.2010.05.084

I. Villacrés-Granda et al., “Honey quality parameters, chemical composition and antimicrobial activity in twelve Ecuadorian stingless bees (Apidae: Apinae: Meliponini) tested against multiresistant human pathogens,” LWT, vol. 140, p. 110737, 2021. doi: https://doi.org/10.1016/j.lwt.2020.110737

I. Prasertsung, K. Aroonraj, K. Kamwilaisak, N. Saito, and S. Damrongsakkul, “Production of reducing sugar from cassava starch waste (CSW) using solution plasma process (SPP),” Carbohydr Polym, vol. 205, pp. 472–479, 2019. doi: https://doi.org/10.1016/j.carbpol.2018.10.090

S. Widiarto, E. Pramono, Suharso, A. Rochliadi, and I. M. Arcana, “Cellulose nanofibers preparation from cassava peels via mechanical disruption,” Fibers, vol. 7, no. 5, 2019. doi: https://doi.org/10.3390/fib7050044

K. S. Tumwesigye, L. Morales-Oyervides, J. C. Oliveira, and M. J. Sousa-Gallagher, “Effective utilisation of cassava bio-wastes through integrated process design: A sustainable approach to indirect waste management,” Process Safety and Environmental Protection, vol. 102, pp. 159–167, 2016. doi: https://doi.org/10.1016/j.psep.2016.03.008

O. P. Olaniyan and E. I. O. Ajayi, “Phytochemicals and in vitro anti-apoptotic properties of ethanol and hot water extracts of Cassava (Manihot esculenta Crantz) peel biogas slurry following anaerobic degradation,” Clinical Phytoscience, vol. 7, no. 1, Dec. 2021, doi: https://doi.org/10.1186/s40816-021-00311-2.

E. Hartulistiyoso, O. Farobie, and M. Zaky, “Delignification of Cassava Peel as Bioethanol Raw Material using Combined Alkali and Microwave Heating Methods,” in IOP Conference Series: Earth and Environmental Science, IOP Publishing, 2022, p. 012021. doi: https://doi.org/10.1088/1755-1315/1038/1/012021

P. S.-N. Nigam and A. Pandey, Biotechnology for agro-industrial residues utilisation: utilisation of agro-residues. Springer Science & Business Media, 2009. doi: https://doi.org/10.1007/978-1-4020-9942-7

V. Kumar, A. Al-Gheethi, S. M. Asharuddin, and N. Othman, “Potential of cassava peels as a sustainable coagulant aid for institutional wastewater treatment: Characterisation, optimisation and techno-economic analysis,” Chemical Engineering Journal, vol. 420, Sep. 2021, doi: https://doi.org/10.1016/j.cej.2020.127642.

O. Oladipo Ol, O. O. Oluwadamil, I. O. Adebola, and A. Juliet Bam, “Hydrolysis of Cassava Peels with Concentrated Cellulase from Bacillus subtilis Improved Its Nutritional Contents,” Asian Journal of Biological Sciences, vol. 13, no. 4, pp. 353–360, Sep. 2020, doi: https://doi.org/10.3923/ajbs.2020.353.360

W. Rogoski, G. N. Pereira, K. Cesca, D. de Oliveira, and C. J. de Andrade, “An Overview on Pretreatments for the Production of Cassava Peels-based Xyloligosaccharides: State of Art and Challenges,” 2023, Springer Science and Business Media B.V. doi: https://doi.org/10.1007/s12649-023-02044-4.

O. O. Olukomaiya, O. Q. Adiamo, W. C. Fernando, R. Mereddy, X. Li, and Y. Sultanbawa, “Effect of solid-state fermentation on proximate composition, anti-nutritional factor, microbiological and functional properties of lupin flour,” Food Chem, vol. 315, Jun. 2020, doi: https://doi.org/10.1016/j.foodchem.2020.126238.

A. P. Sulaeman, Y. Gao, T. Dugmore, J. Remón, and A. S. Matharu, “From unavoidable food waste to advanced biomaterials: microfibrilated lignocellulose production by microwave-assisted hydrothermal treatment of cassava peel and almond hull,” Cellulose, vol. 28, pp. 7687–7705, 2021. doi: https://doi.org/10.1007/s10570-021-03986-5

A. Edhirej, S. M. Sapuan, M. Jawaid, and N. I. Zahari, “Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties,” Int J Biol Macromol, vol. 101, pp. 75–83, 2017. doi: https://doi.org/10.1016/j.ijbiomac.2017.03.045

R. J. Bouza, Z. Gu, and J. H. Evans, “Screening conditions for acid pretreatment and enzymatic hydrolysis of empty fruit bunches,” Ind Crops Prod, vol. 84, pp. 67–71, 2016. https://doi.org/10.1016/j.indcrop.2016.01.041

A. Typas and V. Sourjik, “Bacterial protein networks: properties and functions,” Nat Rev Microbiol, vol. 13, no. 9, pp. 559–572, 2015. DOI doi: https://doi.org/10.1038/nrmicro3508

V. Kumar, A. Al-Gheethi, S. M. Asharuddin, and N. Othman, “Potential of cassava peels as a sustainable coagulant aid for institutional wastewater treatment: Characterisation, optimisation and techno-economic analysis,” Chemical Engineering Journal, vol. 420, Sep. 2021, doi: https://doi.org/10.1016/j.cej.2020.127642

X. Lin, Z. Gou, Y. Wang, L. Li, Q. Fan, F. Ding, C. Zheng and S. Jiang “Effects of dietary iron level on growth performance, immune organ indices and meat quality in Chinese Yellow broilers,” Animals, vol. 10, no. 4, p. 670, 2020. doi: https://doi.org/10.3390/ani10040670

O. Dieudonne, J. Nguefack, J. B. D. Lekagne, C. D. Daboy, and G. N. Mangoumou, “The potential of cassava (Manihot esculenta Crantz) peels as an organic fertilizer,” International Annals of Science, vol. 10, no. 1, pp. 107–117, 2021. doi: https://doi.org/10.21467/ias.10.1.107-117

O. J. Babayemi, O. J. Ifut, U. A. Inyang, and L. J. Isaac, “Quality and Chemical Composition of Cassava VVastes,” Agricultural journal, vol. 5, no. 3, pp. 225–228, 2010. doi: https://doi.org/10.1088/1742-6596/1374/1/012010

G. Cruz, A. da L. P. Rodrigues, D. F. da Silva, and W. C. Gomes, “Physical–chemical characterization and thermal behavior of cassava harvest waste for application in thermochemical processes,” J Therm Anal Calorim, vol. 143, pp. 3611–3622, 2021. doi: https://doi.org/10.1016/j.carbpol.2013.02.008

F. Xu, Y.-C. Shi, and D. Wang, “X-ray scattering studies of lignocellulosic biomass: a review,” Carbohydr Polym, vol. 94, no. 2, pp. 904–917, 2013. doi: https://doi.org/10.1016/j.carbpol.2013.02.008

A. Czaikoski, R. L. da Cunha, and F. C. Menegalli, “Rheological behavior of cellulose nanofibers from cassava peel obtained by combination of chemical and physical processes,” Carbohydr Polym, vol. 248, p. 116744, 2020. doi: https://doi.org/10.1016/j.carbpol.2020.116744

D. C. M. Ferreira, G. Molina, and F. M. Pelissari, “Biodegradable trays based on cassava starch blended with agroindustrial residues,” Compos B Eng, vol. 183, p. 107682, doi: https://doi.org/10.1016/j.compositesb.2019.107682

K.V. Neenu, C.M. Dominic, P. S. Begum, J. Parameswaranpillai, B. P. Kanoth, D.A. David, S. M. Sajadi, P. Dhanyasree, T.G. Ajithkumar and M. Badawi, “Effect of oxalic acid and sulphuric acid hydrolysis on the preparation and properties of pineapple pomace derived cellulose nanofibers and nanopapers,” Int J Biol Macromol, vol. 209, pp. 1745–1759, 2022. doi: https://doi.org/10.1016/j.ijbiomac.2022.04.138

E. D. Asuquo and A. D. Martin, “Sorption of cadmium (II) ion from aqueous solution onto sweet potato (Ipomoea batatas L.) peel adsorbent: characterisation, kinetic and isotherm studies,” J Environ Chem Eng, vol. 4, no. 4, pp. 4207–4228, 2016. doi: https://doi.org/10.1016/j.jece.2016.09.024

C. Tejada-Tovar, A. D. Gonzalez-Delgado, and A. Villabona-Ortiz, “Characterization of residual biomasses and its application for the removal of lead ions from aqueous solution,” Applied Sciences, vol. 9, no. 21, p. 4486, 2019. doi: https://doi.org/10.3390/app9214486

G. K. Dongo, N. J. Nsami, and K. J. Mbadcam, “Ferromagnetic activated carbon from cassava (Manihot dulcis) peels activated by Iron (III) chloride: Synthesis and characterization,” Bioresources, vol. 15, no. 2, pp. 2133–2146, 2020. https://doi.org/10.15376/biores.15.2.2133-2146

E.O. Egbune, T. Ezedom, O. C. Orororo, O.U. Egbune, O. J. Avwioroko, E. Aganbi, A.A. Anigboro and N.J. Tonukari “Solid-state fermentation of cassava (Manihot esculenta Crantz): a review,” World J Microbiol Biotechnol, vol. 39, no. 10, p. 259, 2023.DOI doi: https://doi.org/10.1007/s11274-023-03706-0

N. M. L. Fernando, A. P. S. M. Amaraweera, O. H. P. Gunawardane, W. M. D. B. Wanninayaka, A. Manipura, W. A. R. Manamperi, C. A. Gunathilake, and K. M. A. K. Kulathunga “Sustainable Biorefinery Approach for Cassava: A Review,” Engineer: Journal of the Institution of Engineers, Sri Lanka, vol. 55, no. 2, p. 71, Sep. 2022, doi: https://doi.org/10.4038/engineer.v55i2.7510

C. Hierro-Iglesias, A. Chimphango, P. Thornley, and A. Fernández-Castané, “Opportunities for the development of cassava waste biorefineries for the production of polyhydroxyalkanoates in Sub-Saharan Africa,” Biomass Bioenergy, vol. 166, p. 106600, 2022. doi: https://doi.org/10.1016/j.biombioe.2022.106600

S. R. Mathura, A. C. Landázuri, F. Mathura, A. G. A. Sosa, and L. M. Orejuela-Escobar, “Hemicelluloses from bioresidues and their applications in the food industry–towards an advanced bioeconomy and a sustainable global value chain of chemicals and materials,” Sustainable Food Technology, 2024. doi: https://doi.org/10.1039/D4FB00035H

R. Niayale, W. Addah, and A. A. Ayantunde, “Effects of ensiling cassava peels on some fermentation characteristics and growth performance of sheep on-farm,” Ghana Journal of Agricultural Science, vol. 55, no. 2, pp. 107–121, 2020. doi: https://doi.org/10.4314/gjas.v55i2.9

T. A. Amole, A. B. Adekeye, A. B. Adebayo, I. Okike, A. J. Duncan, and C. S. Jones, “High-Quality Cassava Peel®(HQCP®) mash as a feed ingredient for livestock–a review of feeding trials,” ILRI Project Report, 2022. url: https://creativecommons/

A. B. Adekeye et al., “Growth performance, carcass characteristics and cost benefit of feeding broilers with diets containing high quality cassava peel (HQCP),” Afr J Agric Res, vol. 17, no. 3, pp. 448–455, 2021. doi: http://doi.org/10.5897/AJAR2020.15237

E.O. Egbune, E. Aganbi, A.A. Anigboro, T. Ezedom, O. Onojakpor, A.I. Amata and N.J. Tonukari “Biochemical characterization of solid-state fermented cassava roots (Manihot esculenta Crantz) and its application in broiler feed formulation,” World J Microbiol Biotechnol, vol. 39, no. 2, Feb. 2023. doi: http://doi.org/10.1007/s11274-022-03496-x

A. T. Adeolu and S. O. Adewoye, “Efficacy of cassava peel extracts for the removal of heavy metals from hospital sewage sludge in Nigeria,” J Health Pollut, vol. 9, no. 23, p. 190908, 2019. doi: https://doi.org/10.5696/2156-9614-9.23.190908

Y. Kurnia, D. Jauhariyah, M. Madiyo, Y. Nugraha, M. Akhmansyah, and N. Widiani, “Cassava Peel Extract as Raw Materials for Making Paper: Utilization of Waste as Environmental Conservation,” International Journal of Hydrological and Environmental for Sustainability, vol. 1, no. 3, pp. 160–168, 2022. doi: https://doi.org/10.58524/ijhes.v1i3.1

P. Fronza, A. L. R. Costa, A. S. Franca, and L. S. de Oliveira, “Extraction and characterization of starch from cassava peels,” Starch‐Stärke, vol. 75, no. 3–4, p. 2100245, 2023. doi: https://doi.org/10.1002/star.202100245

T. John, A. Salihu, and E. Onyike, “Assessment of cassava peels as renewable substrate for production of poly-γ-glutamic acid by Bacillus subtilis,” Environmental Sustainability, vol. 3, pp. 179–186, 2020. DOI doi: https://doi.org/10.1007/s42398-020-00102-4

N.A. Acheampong, W. G. Akanwariwiak, M. Mensah, B. Fei-Baffoe, F. Offei, J.A. Bentil, A.Z. Imoro and L.S. Borquaye “Conversion of cassava peels into bioethanol using the OSTEP approach,” Biomass Convers Biorefin, 2022, doi: https://doi.org/10.1007/s13399-021-02149-7

S.B. Li, Y. Qian, Z.W. Liang, Y. Guo, M.M. Zhao and Z.W. Pang “Enhanced butanol production from cassava with Clostridium acetobutylicum by genome shuffling,” World J Microbiol Biotechnol, vol. 32, no. 4, pp. 1–10, Apr. 2022, doi: https://doi.org/10.1007/s11274-016-2022-7.

S. O. Osemwengie, E. I. Osagie, and B. Onwukwe, “Optimization of bioethanol production from cassava peels,” Journal of Applied Sciences and Environmental Management, vol. 24, no. 12, pp. 2077–2083, 2020. doi: https://doi.org/10.4314/jasem.v24i12.11

A. Abomohra, S. Faisal, R. Ebaid, J. Huang, Q. Wang, and M. Elsayed, “Recent advances in anaerobic digestion of lipid-rich waste: challenges and potential of seaweeds to mitigate the inhibitory effect,” Chemical Engineering Journal, vol. 449, p. 137829, 2022. doi: https://doi.org/10.1016/j.cej.2022.137829

I. G. M. Hamissou, K. E. K. Appiah, K. A. T. Sylvie, S. M. Ousmaila, B. Y. Casimir, and Y. kouassi Benjamin, “Valorization of cassava peelings into biochar: Physical and chemical characterizations of biochar prepared for agricultural purposes,” Sci Afr, vol. 20, p. e01737, 2023. doi: https://doi.org/10.1016/j.sciaf.2023.e01737

E. O. Ajala, M. A. Ajala, I. A. Tijani, A. A. Adebisi, and I. Suru, “Kinetics modelling of acid hydrolysis of cassava (Manihot esculanta Cranz) peel and its hydrolysate chemical characterisation,” Journal of King Saud University-Science, vol. 32, no. 4, pp. 2284–2292, 2020. doi: https://doi.org/10.1016/j.jksus.2020.03.003

R. F. Zakariyah, M. O Ojo, K. A. Ajijolakewu, K.B Saliu, R.N Ahmed, T.O. Agbabiaka, and A Sani “Optimisation of Lactic Acid Fermentation from Cassava Peel by Lactobacillus casei (ATCC334),” Microbiol. Res. J. Int, vol. 31, no. 6, pp. 29–42, 2021. doi: https://doi.org/10.9734/MRJI/2021/v31i630325

E. O. Egbune, O. J. Avwioroko, A. A. Anigboro, E. Aganbi, A.-I. Amata, and N. J. Tonukari, “Characterization of a surfactant-stable α-amylase produced by solid-state fermentation of cassava (Manihot esculenta Crantz) tubers using Rhizopus oligosporus: Kinetics, thermal inactivation thermodynamics and potential application in laundry industries,” Biocatal Agric Biotechnol, vol. 39, p. 102290, 2022. doi: https://doi.org/10.1016/j.bcab.2022.102290

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Fatimah Ibrahim Jumare, Madihah Md. Salleh, Nurashikin Ihsan, Huszalina Hussin

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.